Nickel processing industry activities need to prioritize

sustainable and responsible practices to reduce the environmental or social

impacts they cause. Commitment to carrying out this industrial activity can be

demonstrated, among other things, through International Standardization

Organization (ISO) certification.

One of the commitments in implementing nickel processing

with sustainable and responsible practices was emphasized by Harita Nickel.

This commitment is demonstrated through obtaining ISO 14001 certification for

environmental management systems and ISO 45001 for occupational health and

safety management systems.

ISO 14001 : 2015 certification focuses on the effectiveness

of environmental management systems which include important aspects, such as

environmental risk evaluation, regulatory compliance, and continuous

improvement. Meanwhile, ISO 45001: 2018 certification requires a consistent

process in identifying hazards, reducing risks, and preventing injuries and

health problems in the workplace.

To obtain this ISO certification, Harita Nickel underwent a

series of audit activities carried out by auditors from Societe Generale de

Surveillance (SGS) Indonesia. The process of handing over the certificate from

SGS Indonesia to Harita was carried out in Jakarta, Wednesday (13/12/2023).

Director of Health, Safety and Environment (HSE) Harita

Nickel Tonny Gultom said that nickel mining requires a long time and process.

This makes nickel mining activities receive a lot of attention from various

parties, not only from the production aspect, but also social and environmental

responsibility.

Director of Health, Safety and Environment (HSE) Harita Nickel Tonny Gultom (right) receives ISO 14001 certification for environmental management systems and ISO 45001 for occupational health and safety management systems in Jakarta, Wednesday (13/12/2023).

"This certification is very important because it is our

commitment to carrying out sustainable practices. "Therefore, the audit

was carried out from the document aspect to implementation in the field,"

he said in a media discussion about world-class environmental and safety

management in the nickel processing industry in Jakarta, Wednesday.

Harita has been administering ISO 45001 and ISO 14001

certification since 2020, starting with an agreement and commitment to

implementation by all organizational functions in the HSE management system.

Then in 2022 an assessment will be carried out based on the National Standards

for Occupational Safety Management System Certification from the Ministry of

Manpower.

After that, in February 2023 Harita received ISO45001 certification from SGS-United Kingdom Accreditation Service (SGS-UKAS) in the management of occupational health and safety management systems. Nine months later, Harita received ISO 14001 SGS-UKAS certification for environmental management systems.

Various provisions or regulations from the government become our reference in operating, both in social and environmental aspects.

According to Tony, this certification was also obtained

because Harita had identified environmental risks according to established standards.

After carrying out mining activities, reclamation is also carried out to

organize, restore, improve environmental quality and maintain the ecosystem

within.

One of the mining practices also refers to the Decree of the

Minister of Energy and Mineral Resources Number 1827 of 2018 concerning

Guidelines for Implementing Good Mining Engineering Principles. The mining

process starts from clearing the land, stripping top soil, removing overburden,

taking limonite ore to be processed in the factory, closing the mine hole, to

reclamation and revegetation.

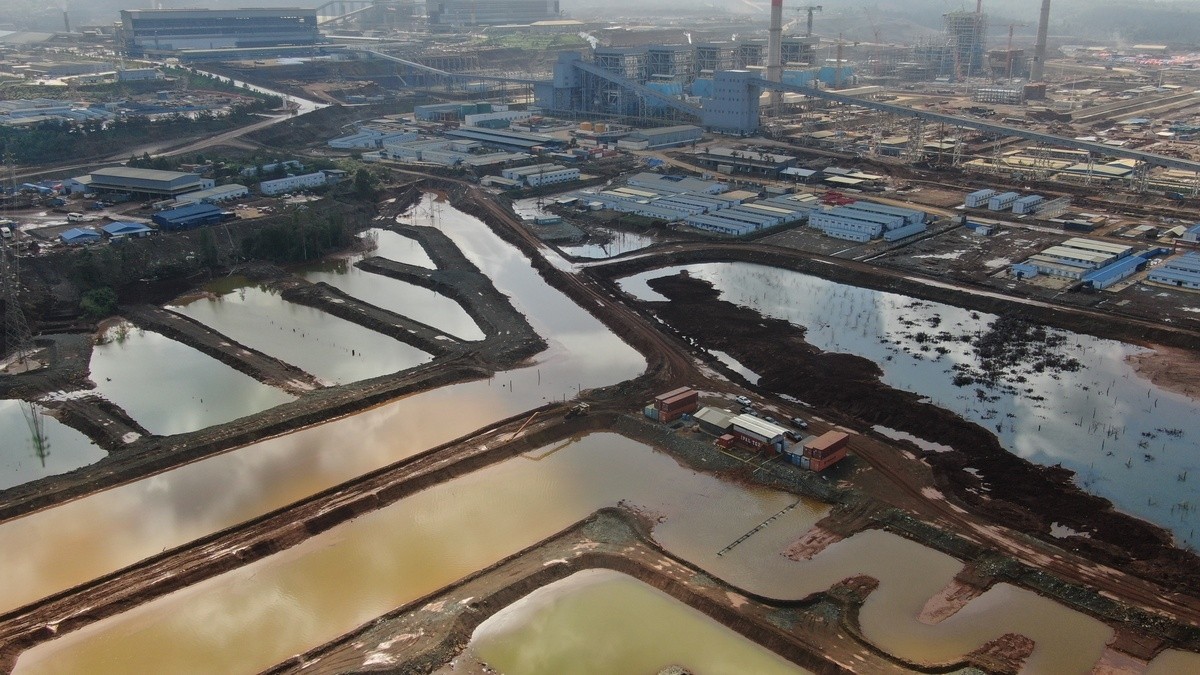

Waste storage ponds in the Harita Nickel group's nickel mining and processing industrial area on Obi Island, South Halmahera, North Maluku, Saturday (25/11/2023).

"In ESDM regulations, reclamation obligations are

referred to international standards. This reclamation is included in the

planning document. In fact, we provide guarantees in the form of reclamation

funds. "The company spends funds twice, namely to carry out reclamation

and the funds are deposited in the bank which can be disbursed if it is

declared to have met the criteria for successful reclamation," said Tonny.

Apart from that, the company also created sediment

ponds as a container for sedimentation to purify the flow of water coming

out of the mining area. Meanwhile, the remaining ferronickel smelter production

is processed into building material products, such as paving blocks and

bricks.

In accordance with the provisions

Occupational Health and Safety (OHS) and Management System

Manager Harita Nickel Suprianto explained that the management of the health,

safety and environmental (HSE) system is carried out in accordance with

applicable laws and regulations. Then, management document guidelines are also

prepared to create controlled and sustainable operations.

"Various provisions or regulations from the government

are our reference in operating, both in social and environmental aspects.

"For example, in emergency management, we are required to make

improvements every year," he said.

SGS Indonesia Knowledge Director Waras Putri Andrianti

stated that getting ISO 14001 and ISO 45001 certification was not easy. This

requires high commitment from management to staff as well as consistent

implementation and continuous improvement of the standards set.

PT Trimegah Bangun Persada Tbk or Harita Nickel is part of

the Harita Group which operates sustainable integrated nickel mining and

processing on Obi Island, South Halmahera, North Maluku. Since 2016, Harita

Nickel has had a nickel saprolite smelter (smelter). Then in 2021, the company

will also have nickel limonite processing and refining facilities (refinery) in

the same operational area.

Harita Nickel is listed as a company with the initiation of

processing and refining nickel limonite (low grade) with high pressure

acid leach (HPAL) technology. This technology is able to process nickel

limonite which was not previously utilized into a product of strategic value in

the form of mixed hydroxide precipitate (MHP).

With the same technology, MHP as an intermediate product has been successfully processed into final products in the form of nickel sulfate and cobalt sulfate which are core material for making cathodes for new energy sources, namely electric vehicle batteries.

Image source: KOMPAS/RADITYA HELABUMI

Source: www.kompas.id/Sertifikasi ISO Tandai Komitmen Pemrosesan Nikel yang Berkelanjutan