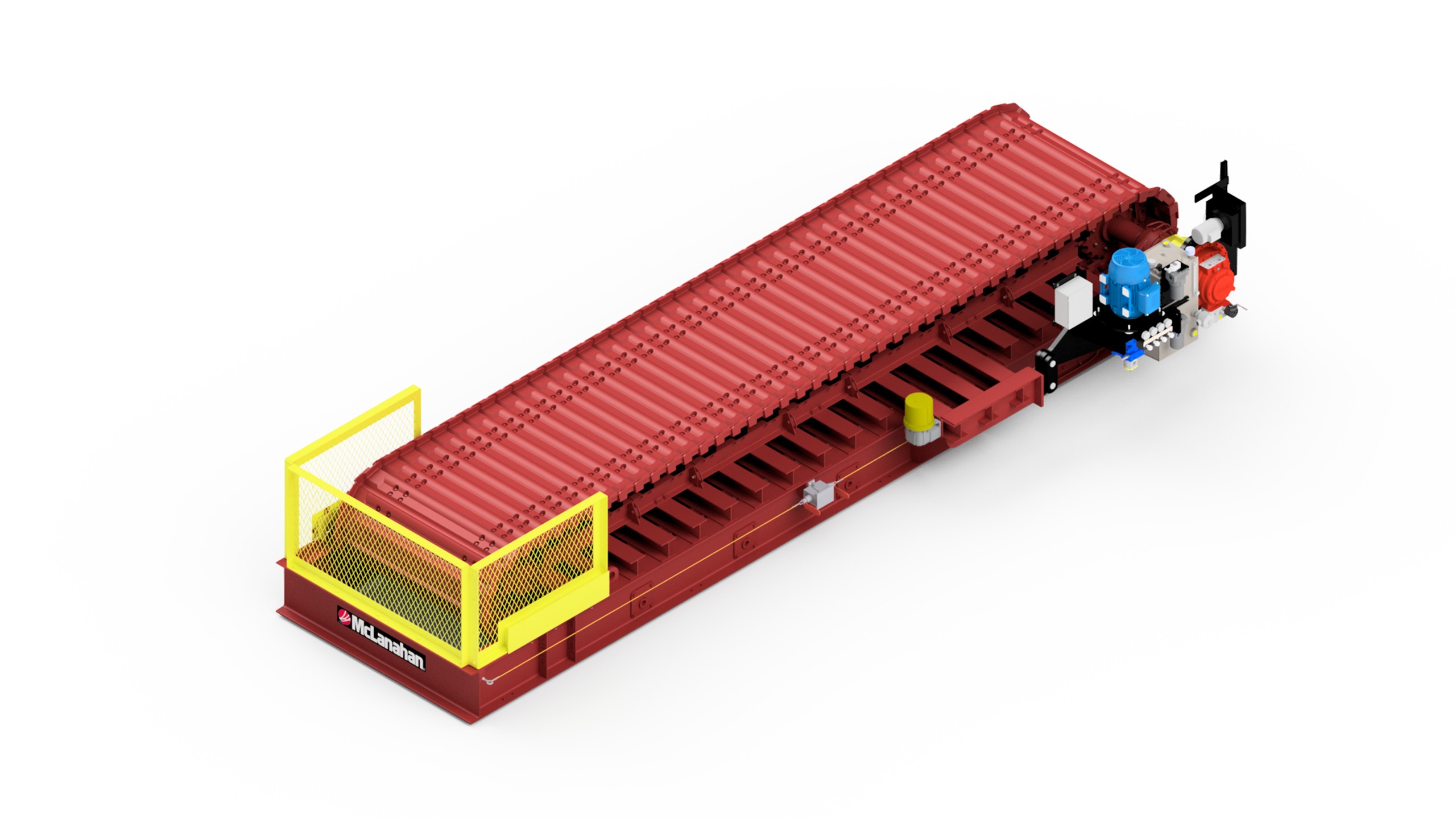

Apron Feeder

Views

Share With Friends

cLanahan Apron Feeders are designed based on a decades-old concept developed by National Iron Company of using a crawler undercarriage. Their reliability has been tested by hundreds of Apron Feeders still operating in the field.

McLanahan Apron Feeders are available in six chain sizes, 16 standard flight widths and an infinite range of lengths — all designed to meet a customer's application requirement.

McLanahan Apron Feeders use sealed-for-life undercarriage components, with oversized head shaft bearings, to reduce monitoring and keep maintenance requirements to a minimum. Designed to provide unmatched reliability, Apron Feeder components include a lubricated chain, carry rollers, return rollers, idler wheels, 100,000 hour bearings and fabricated components. Since there are very few components used in an Apron Feeder, maintenance inventory can often be kept quite low. When maintenance is required, most tasks can take place at the tail-end of the Apron Feeder, which is easily accessible.

Safety pull cords and a zero speed switch are standard features. Unlike other vibratory feeders, when you stop an Apron Feeder, material flow stops immediately.

Apron Feeder flights can be supplied in cast manganese or fabricated, formed steel to fit the duty requirements of the application. This gives ultimate flexibility in having the right feeder duty for the application.

Apron Feeder drive systems can be supplied in electrical-mechanical or hydraulic to match the duty and requirements of the application.