Indonesia Powers Up: First EV Battery Factory Targets Global Exports, Boosts Local Jobs

BNN

1160 Views

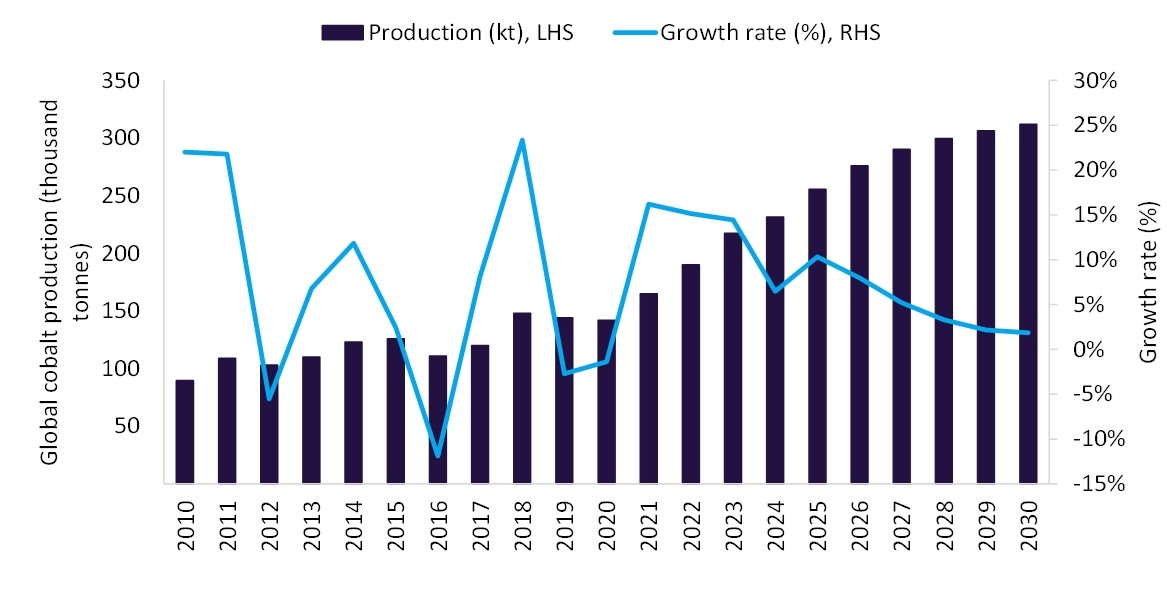

Indonesia's march towards becoming a key player in the global electric vehicle (EV) ecosystem takes a significant leap forward with the commencement of mass production at T Hyundai LG Indonesia (HLI) Green Power's battery factory. Located in Karawang, West Java, this facility is poised to start operations in April, focusing on exporting the majority of its output to South Korean and Indian markets, especially. This venture promises substantial employment opportunities for the local workforce and places Indonesia on the EV map.Strategic Location and Production CapabilitiesThe HLI Green Power factory, boasting a production capacity of 10 gigawatt-hours, can produce up to 32.6 million battery cell units each year. These cells, each with a power capacity of up to 81 ampere-hours or 300 watt-hours, will be crafted using essential materials such as nickel, manganese, cobalt, and lithium. Indonesia's abundant nickel reserves play a crucial role in this equation, providing a strategic advantage in the competitive EV market.Empowering the Local EconomyOne of the factory's notable commitments is to local employment, with over 90 percent of its workforce comprising Indonesians, including positions for junior engineers. This initiative is expected to significantly reduce unemployment rates in the region, offering a beacon of hope for economic growth and stability. The focus on local talent underscores Indonesia's broader ambitions to nurture a skilled workforce that can propel the country forward in the high-tech industry sector.Global Impact and Future ProspectsAs Indonesia gears up to export the majority of its EV battery production, the move is set to redefine the country's position in the global supply chain. This strategic pivot caters to the growing demand for EVs worldwide and aligns with the global efforts to transition towards cleaner, more sustainable modes of transportation. The successful operation of the HLI Green Power factory could pave the way for further investments and advancements in Indonesia's EV infrastructure, potentially making it a hub for green technology in Southeast Asia.The launch of Indonesia's first EV battery factory marks a milestone in the country's industrial evolution. By embracing the global shift towards electric vehicles, Indonesia contributes to environmental sustainability and propels its economy into a future powered by green technology. This development promises to set a precedent for other nations to follow while highlighting the importance of innovation, sustainability, and local empowerment in the journey towards a cleaner planet. Image source: BNNSource: https://bnnbreaking.com/world/asia/indonesia-powers-up-first-ev-battery-factory-targets-global-exports-boosts-local-jobs