Harita Nickel Improves Energy Efficiency in Production Process

Thu 14 Dec 2023, 08:00 AM

Share

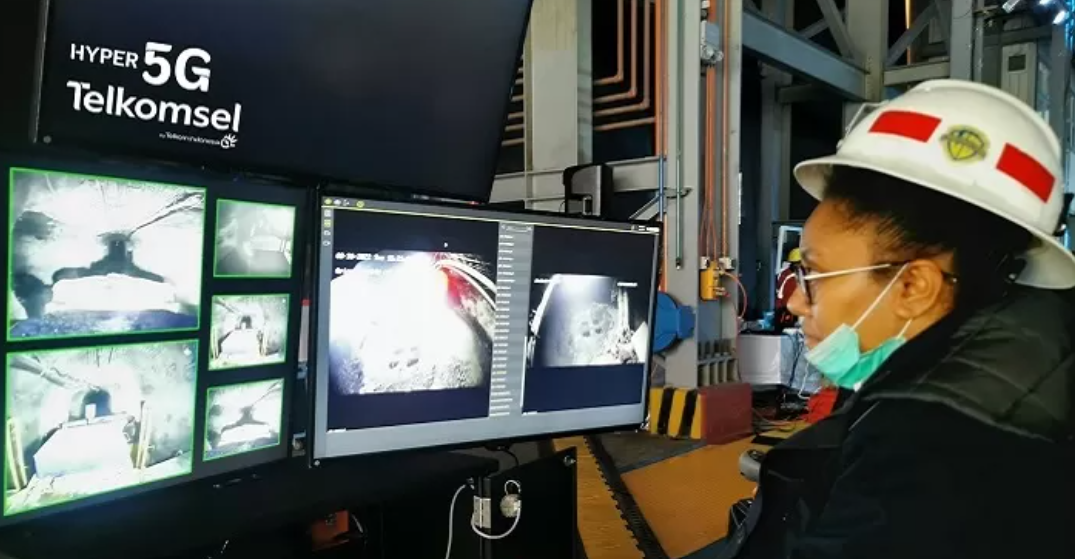

PT Trimegah Bangun Persada Tbk (NCKL) or Harita Nickel

continues to strive for effective and efficient use of energy in the company's

nickel processing process.

Head of Technical Support Harita Nickel Rico Windy Albert

said, one example of optimal energy use in the company's production facilities

has been implemented at one of the nickel smelters operated by a

subsidiary entity, namely PT Halmahera Jaya Feronikel (HJF).

Meanwhile, the smelter processes high grade nickel

ore or saprolite into ferronickel using a pyrometallurgical processing system

called Rotary Kiln Electric Furnace (RKEF).

Rico said, to support the operation of the smelter facility,

the company has 4 steam power generator units, each of which produces 150

megawatts of electricity or a total of 600 megawatts.

"The power produced from this PLTU uses coal

gasification, so the combustion is cleaner," said Rico when met by the EV

Exploration Team in Kawasi, Obi Island, North Maluku.

He said that the effective use of energy in the production

process was carried out by implementing a heat recovery system at each stage of

ferronickel production. He said that the heat recovery system

was implemented so that all the power produced in coal gasification at the PLTU

could be used effectively.

He explained that the excess heat energy produced during the

process of smelting nickel ore in an electric furnace would be utilized in the

previous production stage, namely calcination in a rotary kiln.

Then, the excess heat energy in the calcination process will

also be used in the previous stage of ferronickel production, namely drying

nickel ore.

Apart from that, the HJF smelter also has a water management

system that can be reused in the manufacturing process.

"We have a holding pond to deposit rainwater and used

nickel processing water, we pump it so it can be used by the smelter, so it

doesn't go to waste," said Rico.

Separately, Environmental Superintendent Harita Nickel Indra

Maizar said that the company has a special water management system for use in

nickel production activities. Indra said that Harita Nickel has two

special ponds which function to collect rainwater and water used by production

activities from the smelter.

He said that rainwater that had been collected in the pond

was pumped to the company's smelter facility to be used in the production

process. The waste water used from production is then channeled back into

a different pond for storage.

"The water will later be pumped to the smelter to be used again in the nickel processing process," said Indra.

Image source: JIBI/Bisnis/Fanny Kusumawardhani

Source: www.ekonomi.bisnis.com/Jelajah EV: Harita Nickel Tingkatkan Efisiensi Energi dalam Proses Produksi