Antam is Seriously Developing EV Batteries, Involved in Six Joint Ventures

Thu 17 Jul 2025, 10:19 AM

Share

President Director of PT Aneka Tambang Tbk (Antam), Achmad Ardianto, stated that Antam is seriously pursuing projects related to the electric vehicle (EV) battery ecosystem, spanning from upstream to downstream. The company, listed under the stock code ANTM, is currently involved in at least six joint venture (JV) companies as part of this effort.

This was stated by Achmad in a Hearing Meeting (RDP) with Commission XII of the DPR in Jakarta, Wednesday (16/7).

“This is a long and challenging project, and it still requires government support”, he said at the Parliament Building.

The downstreaming carried out by the Member of the State-Owned Mining Holding Company PT Mineral Industri Indonesia (MIND ID) is currently not limited to the construction of stainless steel projects, but also processes nickel into electric vehicle batteries.

Antam's involvement in six joint ventures, aimed at creating an ecosystem from upstream mining to EV battery manufacturing, includes PT Sumber Daya Arindo (SDA), which operates a nickel mine in East Halmahera, North Maluku.

The mine produces 10 million wet metric tons (wmt) of nickel ore per year, consisting of 7 million wmt of saprolite and 3 million wmt of limonite.

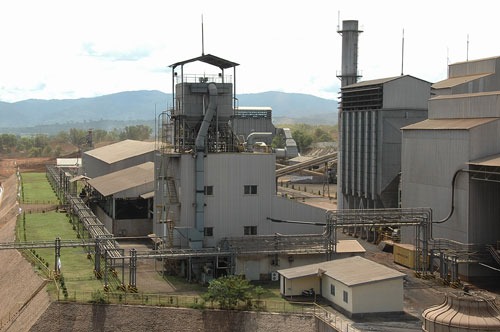

In the next phase, PT Feni Haltim (FHT) operates a Rotary Kiln Electric Furnace (RKEF) smelter and industrial estate. ANTAM holds a 40% stake in this company, while CBL holds the remaining 60%.

PT FHT produces ferronickel with a production capacity of 88 thousand tons per year, and is targeted to officially operate in 2027.

“There will be an industrial area in East Halmahera called FHT, an industrial area for the development of nickel powder which will later be used to build battery materials”, continued Achmad.

Third, there is a joint venture between ANTAM and CBL for the High Pressure Acid Leach (HPAL) smelter in East Halmahera which is projected to be able to produce Mixed Hydroxide Precipitate (MHP) by 2028.

From HPAL, MHP will be processed into nickel sulfate, precursors, and CAM, all three of which are materials used to make electric vehicle batteries. The industry, still located in East Halmahera, is 30% owned by Indonesia Battery Corporation (IBC) and 70% by CBL.

Moving to Karawang, West Java, ANTAM, through IBC together with CBL, has also laid the first stone on an electric vehicle battery factory project that will produce battery cells and modules with a capacity of 15 gigawatt hours (GWh).

In the final stage, Antam also plans to build an EV battery recycling facility in East Halmahera, North Maluku. Still partnering with CBL, IBC now holds a 40% participating interest in the recycling project.

"We hope to produce battery products by 2028, and the battery recycling factory will be commercially operational by 2031", Achmad emphasized.

He also hopes for concrete government support amid the company's commitment to building an EV battery ecosystem. One of Antam's most pressing needs, Achmad continued, is government assurance that nickel-based batteries offer numerous advantages over lithium-based batteries.

In this way, he believes the value of Indonesia's nickel resources can truly be optimized for the nation's prosperity.

“What we need is to ensure that nickel-based batteries become a more attractive option compared to the batteries currently on the market - whether they are lithium-based, sodium-based, or hydrogen-based,” Achmad explained.

Source: https://validnews.id/ekonomi/serius-garap-baterai-ev-antam-terlibat-di-enam-perusahaan-patungan